Our Blog

Controls Methods & Development of a PPE Program

PPE Is the Least Effective Hazard Control Method PPE is worn by workers to minimize exposure to occupational hazards that can cause risks of injury and illness. Examples of PPE include gloves, respirators, safety glasses, full body suits, hard hats, fall protection, aprons, vests, earplugs or muffs, and shoes. Many workplaces will include situations where the

Read More

Review Risk Assessments Periodically

What is a Risk Assessment? In the context of occupational safety and health, a risk assessment is a process that aims to protect workers by preventing injuries and illnesses. A risk assessment includes many specific steps, but they can all be grouped in the following three general steps: 1) Hazard Identification (i.e. what would cause risks of injuries

Read More

Job Hazard Analysis & Job Safety Analysis Review

A Job Hazard Analysis takes a job and breaks it down into individual job steps (or tasks). Hazards are then identified for each job step, followed by the measures required to eliminate or reduce those hazards. Review a JHA/JSA to Keep It Current In its Job Hazard Analysis booklet, OSHA reminds us that reviewing periodically a JHA/JSA ensures

Read More

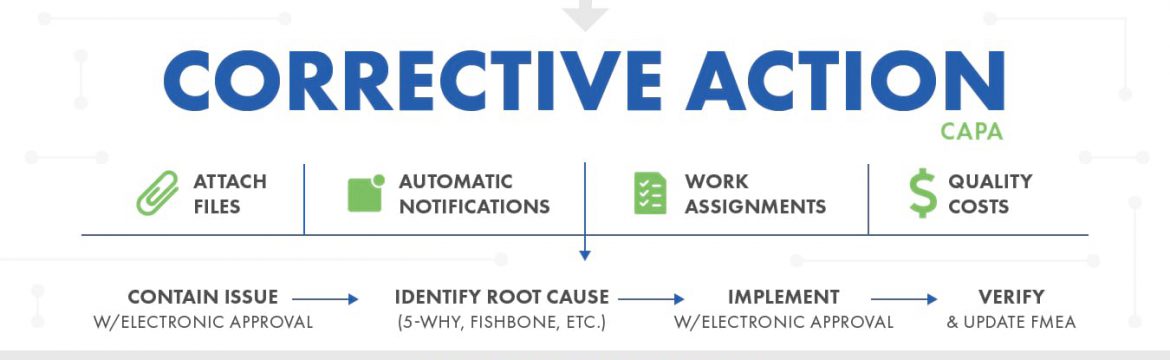

Corrective Actions that Address Root Causes

The Implementation of Corrective Actions Is the Last Step OSHA’s “Incident [Accident] Investigations: A Guide for Employers” document helps organizations implement an incident investigation system composed of the following four steps: 1) Preserve/document the scene2) Collect information3) Determine root causes4) Implement corrective actions According to OSHA’s guidance document, an incident investigation should only be considered complete

Read MoreLaunch Action Plans from Hazard Analysis

Complete Inspections Anywhere & Anytime with Mobility EHS programs include inspections that help to identify workplace hazards that can lead to incidents. In addition to identifying hazards, workplace inspections also help to uncover process weaknesses, which leads to opportunities to improve operational efficiency. A comprehensive inspection program includes both general and special inspections. General inspections are

Read MoreCorrelate Observations with Incident Rates

Use Observations of Unsafe Behaviors as a Leading Indicator To know if you’re doing well, don’t look where you are. Look instead where you’re going. Even if your personal health indicators are good, it doesn’t mean that you’re doing well if you started to eat poorly or sleep less. The same applies to occupational safety.

Read MoreTrain Workers on the Hierarchy of Controls

Train Workers on Hazard Identification and Controls An occupational safety and health (OSH) program also includes training where workers learn more about the OSH program and their responsibilities under it. The training program educates about safety concepts, procedures to follow, how workers can perform their jobs in a safe manner, how to report incidents, and

Read MoreEvaluate the Effectiveness of your Leading Indicators

Leading Indicators Help to Evaluate a Safety Program As part of an occupational safety and health (OSH) program, use both lagging and leading indicators. Lagging indicators measure what has already occurred, such as injuries, illnesses, fatalities, days away from work, etc. They help to comply with regulations that require organizations to keep track of incident

Read MoreWritten Operating Procedures for Unit Startups

Startups & Shutdowns Are More Hazardous Than Normal Operations Recently the U.S. Chemical Safety Board (CSB) released a Safety Digest on Startups and Shutdowns that highlights three incidents that occurred during a startup or shutdown, and provides lessons learned that can be used to prevent future startup and shutdown incidents. Process unit startups and shutdowns are much more hazardous

Read Morethe Pros and Cons of Behaviour Based Safety (BBS)

Behaviour-Based Safety is a program used to inform employees of their overall safety performance. It was founded on the belief that workers can be motivated to behave safely through the use of positive reinforcement. BBS focuses on the actions and behaviors of individual employees. It puts the responsibility of safety on the shoulders of all

Read MoreCategories

- Our Blog (19)

- Uncategorized (3)