10 Simple Workplace, Health & Safety (WHS) tips

These 10 Workplace, Health & Safety (WHS) tips will help you minimise risks and hazards in the workplace. Keep Fire Doors Shut Fire doors must be kept closed at all times (never propped open) if they are to function properly in an emergency. No objects should obstruct fire doors at any time, so if you

Read MoreRoot Cause Analysis During an Accident Investigation

OSHA and EPA Urge Employers to Conduct a Root Cause Analysis OSHA and EPA encourage employers to conduct a root cause analysis following an incident or near miss at a facility. The fact sheet defines a root cause as “a fundamental, underlying, system-related reason why an incident occurred that identifies one or more correctable system failures”. Employers

Read More

Risk Rating for Contractor Work to be Performed

Place Contractors in a Predetermined Risk Category According to the white paper, 9 out of 14 research participants evaluate the risk of the work to be performed by contractors. This is achieved typically through a risk matrix. Contractors are placed in a predetermined risk category, and each risk category may require contractors to take additional steps

Read More

Workplace Inspections – Basic Principles

Workplace inspections help prevent incidents through the critical examination of workplaces. Inspections help identify all types of workplace hazards (biological, chemical, ergonomic, physical), leading to corrective actions. Principles Increase the Effectiveness of Inspections To make workplace inspections as effective as possible, it is helpful to establish and abide by a set of basic principles. The

Read More

3 Different Categories of Leading Indicators

Leading Indicators Are Classified in Three Broad Categories The Campbell Institute at the National Safety Council has published many research reports on leading indicators. One of them, Practical Guide to Leading Indicators: Metrics, Case Studies & Strategies, includes a matrix of key leading indicators, their definitions and associated metrics. The matrix represents a collaborative benchmarking effort

Read More

Controls Methods & Development of a PPE Program

PPE Is the Least Effective Hazard Control Method PPE is worn by workers to minimize exposure to occupational hazards that can cause risks of injury and illness. Examples of PPE include gloves, respirators, safety glasses, full body suits, hard hats, fall protection, aprons, vests, earplugs or muffs, and shoes. Many workplaces will include situations where the

Read More

Review Risk Assessments Periodically

What is a Risk Assessment? In the context of occupational safety and health, a risk assessment is a process that aims to protect workers by preventing injuries and illnesses. A risk assessment includes many specific steps, but they can all be grouped in the following three general steps: 1) Hazard Identification (i.e. what would cause risks of injuries

Read More

Job Hazard Analysis & Job Safety Analysis Review

A Job Hazard Analysis takes a job and breaks it down into individual job steps (or tasks). Hazards are then identified for each job step, followed by the measures required to eliminate or reduce those hazards. Review a JHA/JSA to Keep It Current In its Job Hazard Analysis booklet, OSHA reminds us that reviewing periodically a JHA/JSA ensures

Read More

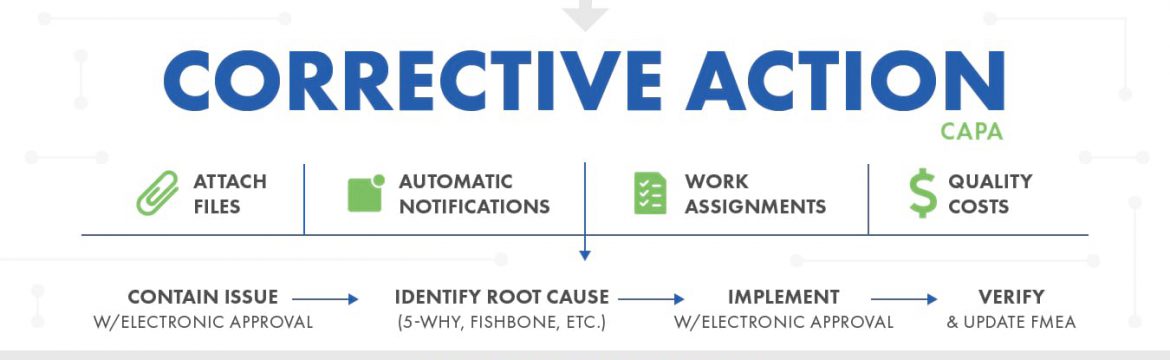

Corrective Actions that Address Root Causes

The Implementation of Corrective Actions Is the Last Step OSHA’s “Incident [Accident] Investigations: A Guide for Employers” document helps organizations implement an incident investigation system composed of the following four steps: 1) Preserve/document the scene2) Collect information3) Determine root causes4) Implement corrective actions According to OSHA’s guidance document, an incident investigation should only be considered complete

Read MoreLaunch Action Plans from Hazard Analysis

Complete Inspections Anywhere & Anytime with Mobility EHS programs include inspections that help to identify workplace hazards that can lead to incidents. In addition to identifying hazards, workplace inspections also help to uncover process weaknesses, which leads to opportunities to improve operational efficiency. A comprehensive inspection program includes both general and special inspections. General inspections are

Read More